- Home

- Company Profile

-

Services

- Projects

- Blogs

- Contact Us

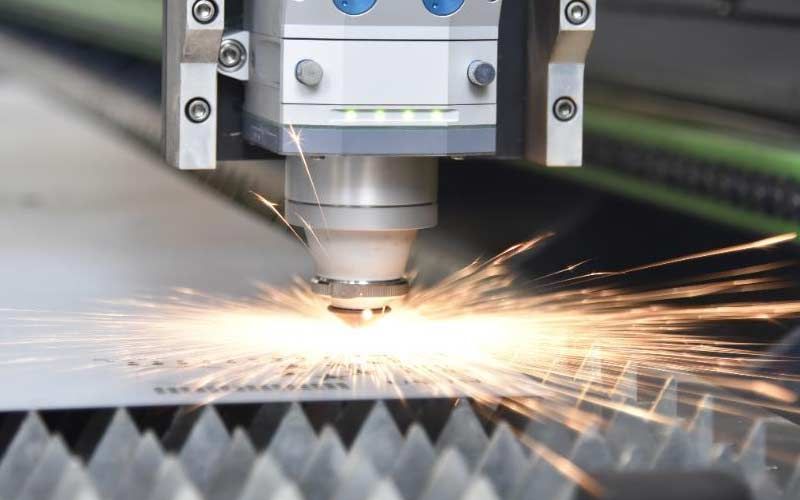

Efficiency is not merely a target in the fast-paced production world of today; it is a competitive advantage. The utilization of saved seconds and perfected cuts determines the speed, quality, and profitability of a production process. The Laser Cutting Services offered by Brisk Steel are the main reason smart manufacturers have chosen to invest in technologies that radically change the way fabrication is done. They offer absolute accuracy, great speed, and consistency in a problem-free operation, which is why laser manufacturing techniques are becoming more and more popular across different industry sectors. In essence, laser cutting is the perfect blend of innovation and the skilled hand of the artisan, irrespective of whether it is metal fabrication, automotive production or industrial design.

To adapt to today's market, manufacturing excellence must be versatile. Laser cutting effortlessly enables market demands such as customized designs, rapid prototyping, and short lead times. Changing from one material to another or adjusting cutting parameters can be done instantly, thus making it an indispensable technology for agile production systems.

In situations where there is a need for fine detailing and speedy production, laser cutting is the method that is mostly used. However, CNC Cutting Services are still very much relevant in precision engineering. CNC machining is the method that is used to achieve dimensional accuracy and maintain structural integrity in parts where the tolerance levels are extremely tight. In most cases, manufacturers use both laser and CNC cutting technologies to get the perfect combination of speed and strength. An instance of these techniques could be a laser-cut part to get an intricate shape and then CNC-machined to refine the joints or threads. With this hybrid method, the industries can make products that meet not only the design requirements but also the mechanical reliability standards necessary for industrial, automotive and aerospace applications.

True manufacturing efficiency is not solely the result of faster machinery but mainly from more intelligent systems. Laser cutting adoption in manufacturing environments is just one part of a bigger ecosystem of lean production and sustainable manufacturing. Less scrap, energy savings, and shorter production runs are just a few of how these changes are contributing to operational excellence.

Accurate, reliable and repeatable are the key factors that define great Mechanical Works. These factors are all improved by laser cutting technology. Mechanical fabrication requires components to fit tightly within assemblies, withstand pressure, and operate under highly specific conditions. Laser cutting meets all these needs by ensuring the design and product are identical. Mechanical engineers use the consistency of laser cutting to produce the least possible deviations of components like gears, brackets, frames, and housings. Moreover, its capability to handle different material thicknesses is an additional factor that leads to the innovation of mechanical design, thus the production of lightweight structures with no loss of strength.

Laser Cutting Aids have changed from being just a tool in the manufacturing process to becoming the main driver of industrial change. Their power extends far beyond a single industry and has become the main source for product innovation, environmental impact reduction and overall production quality improvement. For manufacturers who want to keep their leading position, the use of laser technology is not only about metal cutting but also about reducing resource waste. While industries are getting automated and digitally transformed, laser cutting can be considered one of the smartest manufacturing methods, which is the integration of technology, creativity and accuracy in one single laser beam.

Dive into our latest blogs for expert insights, industry trends, and behind-the-scenes looks at our projects. From fabrication tips to event setup ideas, we share valuable knowledge that inspires and informs. Stay updated with fresh content that reflects our innovation, craftsmanship, and dedication to delivering top-quality services across metal works, CNC cutting, event fabrication, and more.

Dubai's real estate market is so dynamic and yet offers a beautiful blend of luxury and innovation. Property owners always strive to enhance their spaces and one common question they keep asking ...

Read More

Dubai is fantastic for its events, grand festivals, and vibrant celebrations. Actually, the art of lighting always plays a role in a city like this. You have a corporate event, and then you have a wed...

Read More

Dubai has become the proposed main landing site for global events - whether corporate launches, beautiful weddings, or major festivals. In such a highly competitive and visually rich environment, the ...

Read More

Dubai is famous for its beautiful architectural structures and rapid development and is becoming greener in its construction and other infrastructure projects. Besides that, being an important part of...

Read More

Superior event fabrication is an ultimate differentiator for successful and memorable occasions. An eminent name in the industry, Brisk Steel, stands tall by providing an all-encompassing Events Fabri...

Read More

It is indeed true that modern technology has had an enormous impact on the fabrication industry. Brisk Steel is one of the leaders in this transformation, incorporating the advanced CNC Cutting Servic...

Read More

In a digitally multitasked world where efficiency drives success, your workspace is more than just a physical arrangement; it reflects how you think, pl...

Read More

In the fast moving world of modern manufacturing precision is not just a goal it is a requirement This demand for perfection is why CNC Cutting Services provided by Brisk Steel have become the backbon...

Read More

Choosing the right Mechanical operations provider has to be one of the most critical steps in making your project a success With custom designed machinery installed industrial equipment or special bui...

Read More

Planning a massive conference or a music festival requires managing a mountain of visual information Modern audiences want a high level of engagement and clear visibility from every single seat...

Read More

Creating a memorable event in a world class city like Dubai requires more than just planning it demands expert craftsmanship and a commitment to perfection...

Read More